Description of DTF Printer

DTF (Direct naar film) printing is a new digital printing technology, particularly suitable for textiles and garment printing. This technology allows images to be printed directly onto a special film, which is then transferred onto fabrics or other materials using a heat press. DTF printing is considered a complement or alternative to traditional screen printing, DTG (Direct To Garment) printing, and sublimation printing.

How DTF Printing Works

1.Design Preparation:

Create or import the image using design software (like Adobe Photoshop or Illustrator).

Adjust the image to the appropriate resolution and size for printing.

2.Print onto Film:

Print the design onto a special DTF transfer film using DTF ink, typically including CMYK and white ink layers.

The white ink layer is used to provide an opaque background on colored or dark fabrics, ensuring the true reproduction of image colors.

3.Apply Powder:

Sprinkle a layer of hot melt powder adhesive onto the printed image. This powder melts when heated and adheres to the image, forming a bonding layer.

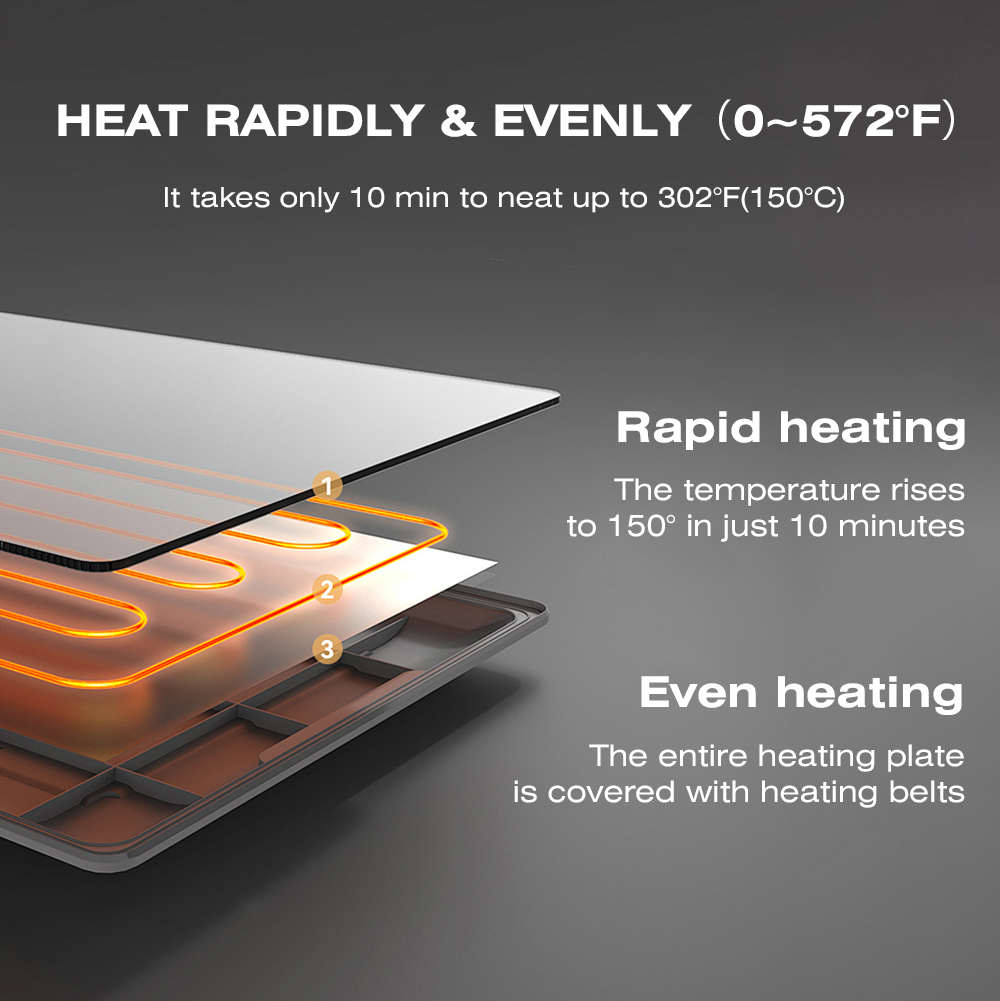

Heat the film on a heat plate to melt the hot melt powder adhesive and make it stick to the ink.

4.Heat Transfer:

Align the processed film with the target fabric surface and place it in a heat press.

Use high temperature and pressure to transfer the image from the film onto the fabric. The hot melt powder adhesive plays a crucial role in this process, ensuring the image adheres firmly to the fabric.

5.Cooling and Peeling:

After the transfer is complete, allow the film and fabric to cool.

Once cooled, carefully peel off the film, leaving the image on the fabric surface.

Advantages of DTF Printing

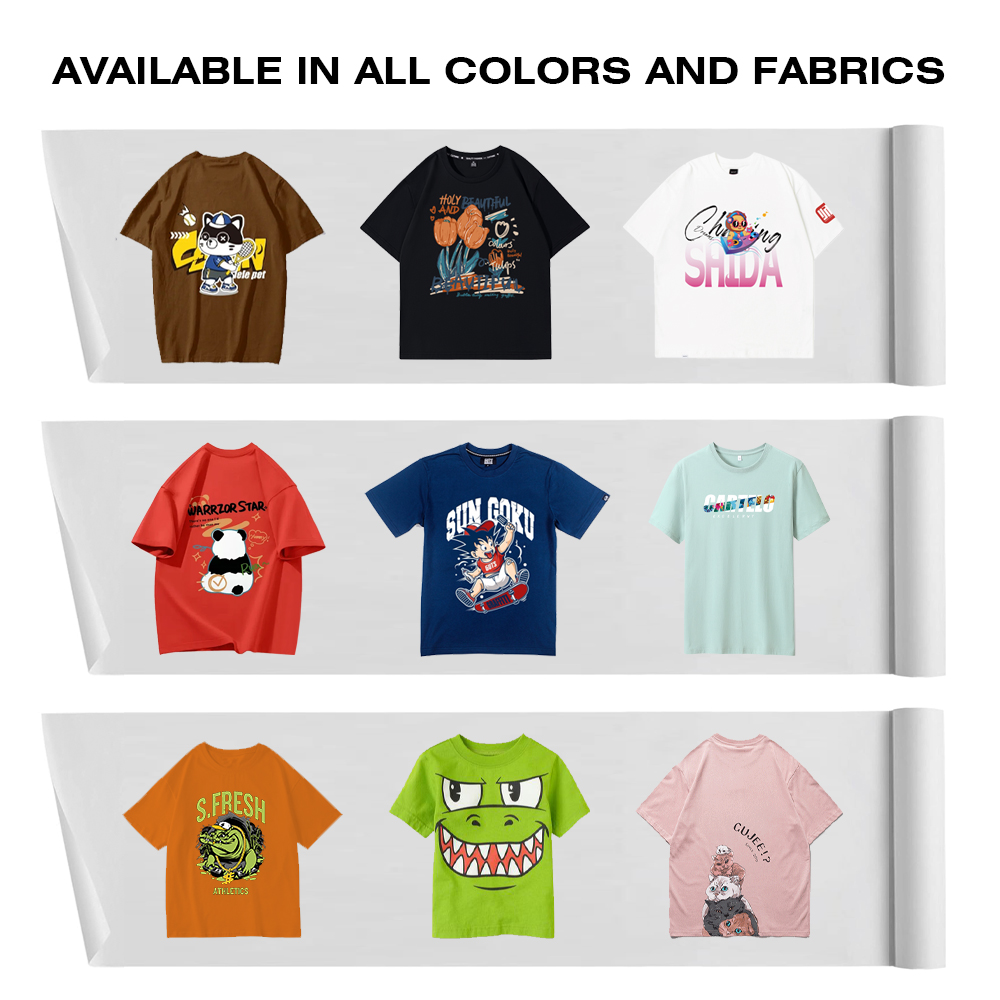

Wide Application: DTF printing can be used on various fabric materials, including cotton, polyester, and blends.

Vibrant Colors: Due to the use of white ink layers and hot melt powder adhesive, images on dark and colored fabrics have high color vibrancy and contrast.

Durability: Transferred images have high wash and wear resistance, not easily fading or peeling.

High Flexibility: DTF printing does not require template making, making it suitable for small batch and customized printing needs.

Steps to Use a DTF Printer

1.Prepare DTF Printer and Supplies:

Ensure you have a suitable DTF printer and special inks, films, and hot melt powder.

Set up the printer, ensuring the print head and nozzles are clean.

2.Print the Image:

Open the design file and adjust the print settings.

Print the image onto the DTF film, ensuring the white ink layer is evenly covered.

3.Apply Powder and Heat:

Sprinkle hot melt powder evenly onto the image.

Use a heating plate to preheat the film, solidifying the hot melt powder.

4.Transfer the Image:

Place the film onto the target fabric and use a heat press to transfer it.

Set the appropriate temperature and pressure, usually between 160-180°C (320-356°F), for 15-20 seconden.

5.Complete the Transfer:

Allow the film and fabric to cool, then carefully peel off the film.

Check the image transfer to ensure there are no defects or peeling.

By following these steps, DTF printing technology can achieve high-quality, duurzaam, and vibrant image transfers, making it an ideal choice for textile and garment custom printing.